NAGSIM - FEA SIMULATION SOFTWARE

NAGSIM.2D allows the user to model the part forming operation in a computer before running it in the machine. NAGSIM.2D provides information to:

- Reduce die trials and costly mistakes

- Improve tool life

- Predict defects

- Optimize sequence design

- Determine mechanical properties of formed part

- Determine the optimum heat treatment of incoming wire / rod.

- Shorten print-to-part time

NAGSIM.2D is a finite element software program for the computer simulation of two-dimensional metal forming processes. It can simulate large plastic deformation of the part as well as the elastic deformation of the tools. It complements ‘NAGFORM’, a knowledge-based program to create alternative forming sequences to form a part. NAGSIM.2D and NAGFORM together present a breakthrough in the development and optimization of forming sequence for a part.

A Complete and Easy-to-Use Solution – NAGSIM.2D provides a complete and easy-to-use solution from creating a model of the forming operation to post-processing of simulation results. NAGSIM.2D’s graphical user interface is tailored specially for simulating metal forming operations. It is very user-friendly and intuitive to use.

Efficient and Robust Solver- NAGSIM.2D uses an incremental finite element analysis solver that is suited to metal forming operations with large plastic deformation. Two types of problems can be analyzed:

- Plane Strain – representing deformation of long parts

- Axisymmetric – representing deformation of round parts

Material Database – NAGSIM.2D has a database of materials commonly used in cold forming. New materials can be easily created and stored in the database. The flow properties of the material are defined dependent upon strain and strain rate.

Automatic Meshing and Remeshing – NAGSIM.2D incorporates an automatic element mesher. After the deformation process starts, the program automatically remeshes the part if the old mesh gets excessively distorted or if it is desired to mesh certain areas with finer mesh.

Elastic Stress of Tools– Using NAGSIM, the user can predict the principle stresses in the tool. The fatigue life of a tool is directly proportional to the numeric values of the stresses in a tool during a forming cycle.

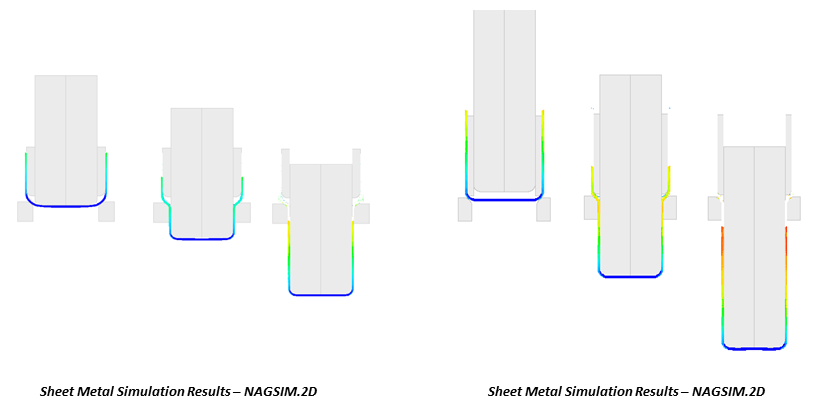

Results and Information – NAGSIM.2D provides a complete insight into the forming process. The results include: Material flow, stress distribution, strain distribution, formation of laps, force distribution, tool stresses and contact between the part and the tools. Animation presents a clear visual of the forming operation. Tensile damage, grain flow and tracing deformation path of a point are included in the results.

Link with NAGFORM – NAGFORM and NAGSIM.2D work together to provide the shortest path to develop forging process for manufacturing a part. Sequence designs created in NAGFORM can be transferred effortlessly to NAGSIM.2D. NAGFORM creates ‘Generic’ tooling for a sequence and prepare an analysis file automatically. This analysis file is used by NAGSIM.2D to preform metal flow simulation.

Mini CAD System – NAGSIM.2D program includes a user friendly mini ‘CAD’ system. Using this, the user can create the part and tool drawings or modify the imported drawings within NAGSIM.

NAGSIM.3D- is a general purpose finite element analysis (FEA) software program for the computer simulation of three dimensional metal forming processes. NAGSIM.3D can simulate large plastic deformation of the part. Its powerful solver uses a modified tetra element that allows automatic meshing of complex parts.

NAGSIM.3D can be used to:

- Predict metal flow

- Eliminate costly die trials and mistakes

- Predict defects and high stress / strain areas

- Optimize the forging sequence

- Determine mechanical properties of the formed part

- Determine the optimum heat treatment of incoming wire / rod.

- Improve tool life

NAGSIM.3D’s graphical user interface is tailored for simulating metal forming operations. It is very user-friendly and intuitive to use. NAGSIM.3D provides a complete insight into the forming process. The results include: Material flow, stress distribution, strain distribution, formation of laps, force distribution and contact between the part and the tools. Animation presents a clear visual of the forming operation.

Integration with NAGSIM.2D – NAGSIM.3D has the capability to bring in results of NAGSIM.2D simulation for the previous operation including strains. The program converts the 2D results into 3D by revolving the 2D section. This feature is extremely beneficial for Users that form parts in multiple operations. The initial 2D operations can be analyzed in NAGSIM.2D and the final operations involving 3D geometry are simulated in NAGSIM.3D program.

Preprocessor – NAGSIM.3D provides a simple method of importing geometry of the tools and the initial blank drawings into the program.

Advantages over Competitors – NAGSIM.3D is an efficient and cost effective FEA software product. Following are some features over its competitor programs:

- Cost Effective Product

- User Friendly

- Predefined templates for ease in set up of a simulation process.

- Easy transition from NAGSIM.2D to NAGSIM.3D

The current version of NAGSIM.3D include:

- Elastic Stress Analysis of the Tools.

- Thermal Analysis. NAGSIM.3D can be used for cold, warm and hot forged processes.

- Time Dependent Motion Boundary Conditions.

- Volume Mesher for Non Uniform Mesh – based on Delaunay Incremental Method

- Import Deforming Part Model in STL Format.

For more information on our Sheet Metal related products, please visit

NAGSIM Simulation for Sheet Metal Parts

NAGSIM is a finite element software (FEA) program for the computer simulation of dimensional metal forming processes. It can simulate large plastic deformation of the part as well as the elastic deformation of the tools. It complements ‘NAGFORM’, a knowledge-based program to create alternative forming sequences to form a part. NAGSIM and NAGFORM together present a breakthrough in the development and optimization of forming sequence for a part.

NAGSIM.2D – NAGSIM.2D is a finite element software program for the computer simulation of two-dimensional metal forming processes.

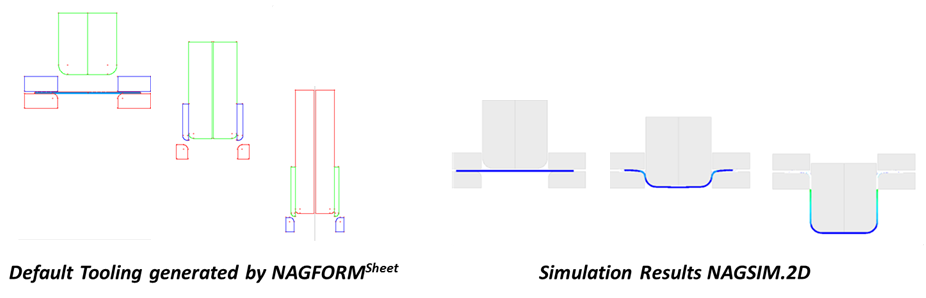

NAGFORM/Sheet Integration with NAGSIM.2D – In NAGFORM/Sheet, simulation files for NAGSIM.2D can be automatically created for any selected part progression generated in Auto Design. To simulate, the user opens this file in NAGSIM.2D, meshes the parts and begins simulating. It takes only couple of minutes to go from NAGFORM’s design concept to NAGSIM.2D simulation.

NAGSIM.2D_Bimetal is a special version of NAGSIM.2D that simulates large plastic deformation of two deforming parts in an application. The program allows the user to model the forming operation in a computer before running it in the machine. NAGSIM.2D Bimetal provides information to:

- Predicts how two deforming materials would plastically deform under load

- Predict defects in bimetal forming applications

- Optimize the process of forming bimetals

- Determine mechanical properties of the formed part

- Determine the stresses at the interface of the two deforming metals.

NAGSIM.2D Bimetal, like NAGSIM.2D, is a finite element software program for the computer simulation of two-dimensional metal forming processes.

A Complete and Easy-to-Use Solution – NAGSIM.2D Bimetal provides a complete and easy-to-use solution from creating a model of the forming operation to post-processing of simulation results. NAGSIM.2D Bimetal ‘s graphical user interface is tailored specially for simulating metal forming operations. It is very user-friendly and intuitive to use.

Efficient and Robust Solver– NAGSIM.2D Bimetal uses an incremental finite element analysis solver that is suited to metal forming operations with large plastic deformation. The conditions of slip at the interface between the two metals can be specified by the User.

Material Database – NAGSIM.2D Bimetal has a database of materials commonly used in cold forming of bimetal parts. New materials can be easily created and stored in the database. The flow properties of the material are defined dependent upon strain and strain rate.

Automatic Meshing and Remeshing – NAGSIM.2D Bimetal incorporates an automatic element mesher. After the deformation process starts, the program automatically remeshes the two deforming materials if the old mesh gets excessively distorted. The interface between the two metals is precisely maintained during the remeshing.

Elastic Stress Analysis of Tools– Using NAGSIM.2D Bimetal, the user can predict the principle stresses in the tool. The fatigue life of a tool is directly proportional to the numeric values of the stresses in a tool during a forming cycle.

Results and Information – NAGSIM.2D Bimetal provides a complete insight into the forming process. The results include: Material flow, stress distribution, strain distribution, formation of laps, force distribution, tool stresses and contact between the part and the tools. Animation presents a clear visual of the forming operation.

Mini CAD System – NAGSIM.2D program includes a user friendly mini ‘CAD’ system. Using this, the user can create the part and tool drawings or modify the imported drawings within NAGSIM.

NAGSIM_Gen.2D is a powerful, general- purpose nonlinear finite element analysis (FEA) software program that quickly and accurately simulates two dimensional hot, warm or cold metal forging processes. It can simulate large plastic deformation of the part as well as elastic deformation of the tools.

NAGSIM_Gen.2D is advanced and general-purpose extension of NAGFORM.2D program for simulation of cold forging processes, with additional capabilities of temperature analysis during deformation.

Eliminate Trial & Error in Forming – NAGSIM_Gen.2D allows you to model the part forming in a computer before running it in the machine. NAGSIM_Gen.2D provides accurate information to:

- Reduce die trials and costly mistakes.

- Improve tool life.

- Predict under fill, laps and cracks.

- Optimize forging sequence and tooling design

- Predict temperature and density distribution.

- Determine mechanical properties of formed part.

- Shorten print-to-part time

- Improve part quality

It complements ‘NAGFORM’ and ‘NagForge’, knowledge-based programs to create alternative forming sequences to form parts by cold, warm or hot forging processes.

A Complete and Easy-to-Use Solution – NAGSIM_Gen.2D provides a complete and easy-to-use solution from creating a model of the forming operation to post-processing of simulation results. NAGSIM_Gen.2D’s graphical user interface is tailored specially for simulating metal forming operations. Templates for common forming operations are provided to reduce the effort required to create the analysis file. NAGSIM_Gen.2D has its own basic CAD module to create geometry of the workpiece and the tools. The part geometry can also be imported in DXF format from other CAD systems such as AutoCad, SolidEdge, SolidWorks etc.

Efficient and Robust Solver – NAGSIM_Gen.2D uses an incremental finite element analysis solver, based on thermo-visco plastic formulation, that is specially suited to metal forming operations with large plastic deformation. Two types of problems can be analyzed:

- Plane Strain deformation: Section of long parts.

- Axisymmetric deformation of round parts.

Material Database- NAGSIM_Gen.2D has a database of materials commonly used in cold, warm and hot forging. New materials can be easily created and stored in database. The flow properties of the material are defined dependent upon strain, strain rate and temperature. A subprogram is provided to analyze compression test data for flow stress formulation.

Automatic Meshing and Remeshing – NAGSIM_Gen.2D incorporates an automatic element mesher. After the deformation process starts, the program automatically remeshes the part when the old mesh gets excessively distorted or it is desired to mesh certain areas with finer mesh. Different remeshing schemes are available.

Elastic Analysis of Tools – Elastic stress analysis of tools is performed for the whole deformation cycle, providing a complete picture of tool stresses during forming.

Mini CAD System – NAGSIM.2D program includes a user friendly mini ‘CAD’ system. Using this, the user can create the part and tool drawings or modify the imported drawings within NAGSIM.

Cold, Warm Forging and Hot forging – NAGSIM_Gen.2D can simulate cold forming as well as warm and hot forging with different temperatures of the part and the tools. Its formulation includes dependence of the flow stress of the material on temperature, strain and strain rate. Speed characteristics of forging machines such as presses can be included in the analysis. The movies below show (a) how the temperature rises in a cylinder and the flat dies during cold upsetting and (b) temperature distribution during hot forging of a side gear.

Results and Information – NAGSIM_Gen.2D provides a complete insight into the forming process. The results include: Material flow, stress distribution, strain distribution, temperature distribution, formation of laps, load-displacement, tool stresses and contact between the part and the tools. Animation of results presents a clear visual of the forming operation. Grain Flow and Tracing deformation path of a point are included in the results.